Metal carved board: coarse brick pattern

Metal carved panels have excellent thermal insulation performance and rich and vivid decoration results. They are usually installed on external walls, so how to install metal carved panels? After ordering the metal carved board and its accessories, it is necessary to prepare tools for installing the board and accessories

Metal carved board manufacturer: How to install metal carved boards?

Metal carved panels have excellent thermal insulation performance and rich and vivid decoration results. They are usually installed on external walls, so how to install metal carved panels?

Step 1: Preparation phase

After the ordered metal carving board and its accessories are complete, it is necessary to prepare tools for installing the board and accessories. Important tools include shrinkage screws, dovetail nails, pistol drills, air nail guns, marking pens, tape measures, rubber hammers, and cutting machines.

Step 2: Install the accessory base

Before installing metal carved boards, the base of the board accessories should be installed first, mainly including starting parts, closing parts, edge wrapping, middle seams, and internal and external corners.

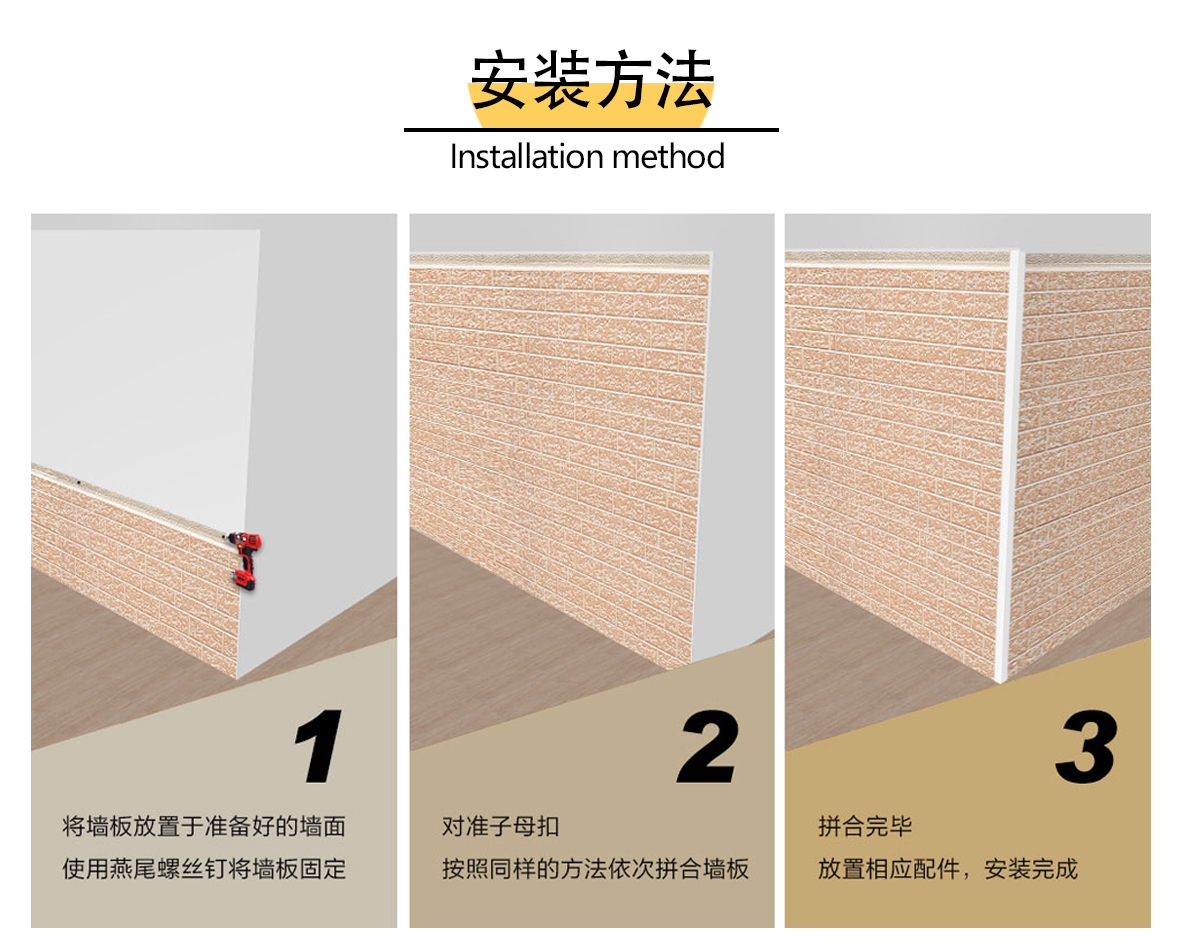

Step 3: Install the board

After installing the base of the accessories, install the first metal carved board horizontally from top to bottom, with the female mouth facing down and the male mouth facing up. After installing the first board, use expansion screws or dovetail nails to secure it to the wall (fixing one nail every 60 cm), then aim the female port of the second board towards the male port of the first board and insert it tightly downwards. At the same time, use a rubber hammer to buckle the interface between the two boards to ensure that the connection between the two boards is sufficient and tight, Then the second board can be fixed to the wall using expansion screws or dovetail nails, and the remaining boards can be installed in the same way.

Step 4: Install the accessory cover plate

After all the metal carving boards are installed, press the accessory cover plate firmly under the base. If it is a component of the same material, it can be fixed to the wall with screws and finally sealed with waterproof glass adhesive.

Step 5: Tear off the protective film of the metal carved board profile

In order to protect the surface layer of metal carved boards from scratches during transportation, all factory produced boards are covered with protective film cages on their surfaces. This way, after the boards are installed, we can remove the protective film, which can make the building look new.

The metal carved board uses environmentally friendly raw materials (such as the inner polyurethane layer and the insulation layer inside the refrigerator and air conditioner being the same material), which are non-toxic, odorless, and pollution-free, providing green protection and decoration for the building.

1. Good insulation performance, which can significantly reduce heating and cooling energy consumption and save energy expenditure

2. Fire retardant, triple protection, no toxic gas generation

3. Waterproof and moisture-proof, to avoid structural damage caused by rain, snow, freezing, melting, etc. After installation, the possibility of water seepage on the wall can be removed

4. Insulation and sound insulation layer, sound insulation and noise reduction, with an independent enclosed bubble structure inside, with good sound insulation effect

5. Fast construction, cost saving, simple and fast installation method, not limited by seasonal climate and geographical environment

6. Environmentally friendly and durable, pollution-free, with stable chemical and physical structures that will not decompose and mold

7. Shock resistant and crack resistant, with light weight, high strength, and good impact resistance, reducing the burden on the building itself

8. With strong decoration, the combination of authentic relief patterns and rich colors provides greater space for architectural design to play

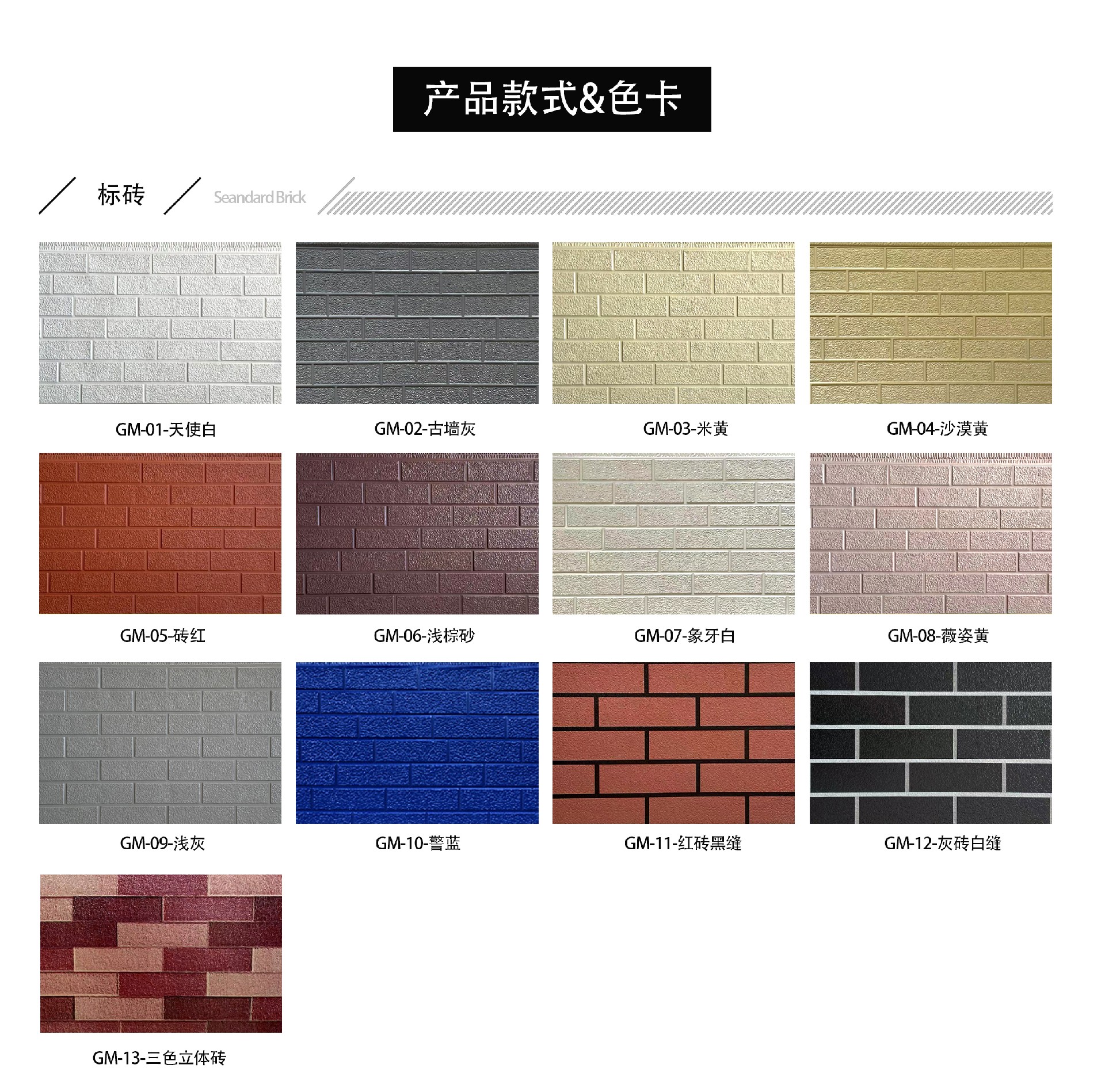

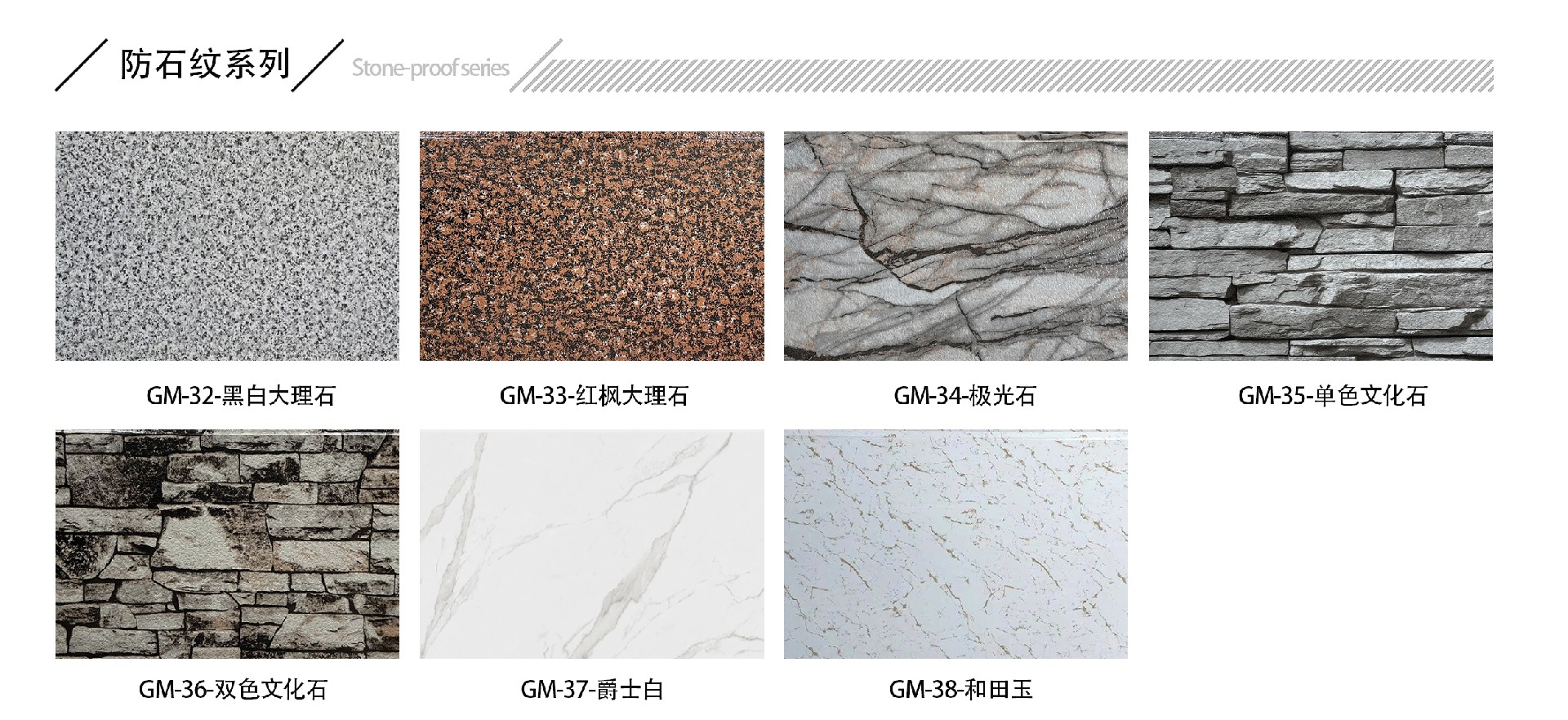

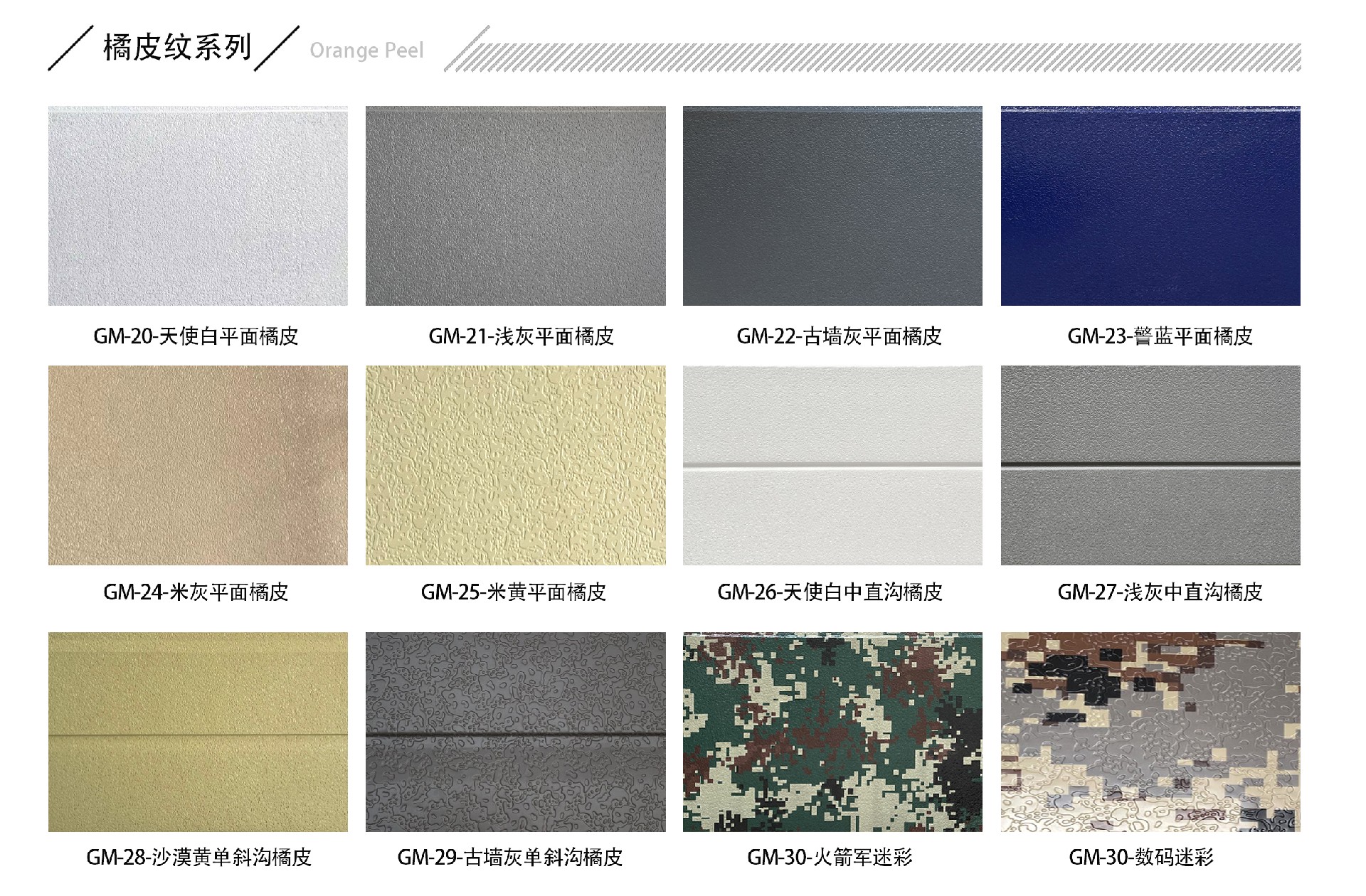

9. There are a variety of designs and colors, including over 100 varieties such as brick, stone, and marble patterns, and more than 50 colors for you to choose from

10. Widely used in various fields, including renovation of old buildings, indoor and outdoor decoration, and various new buildings. It can be used as wall panels, ceiling panels, and decorative panels. 11. It has a long service life and is coated with aluminum zinc steel plates on the outer layer, without considering issues such as rust or peeling.

11. Good cost-effectiveness, the cost of this panel project is one-third of that of the aluminum plastic panel curtain wall project, and the decoration effect is excellent.